Paper bags look simple.

Until you start sourcing them at scale.

From the outside, a paper bag is just folded paper with a logo. From the factory side, it is a chain of decisions—material, printing, structure, bonding, and inspection—that directly affect strength, appearance, cost, and delivery stability.

I have learned one thing from years of production experience: buyers who understand how paper bags are made make fewer mistakes. And suppliers who can clearly explain the process usually run more reliable operations.

This article walks through commercial paper bag manufacturing, step by step.

Step 1 – Paper Selection for Commercial Paper Bags

Everything starts with paper.

Not all paper is suitable for bag production. The paper must survive printing, folding, gluing, filling, and transport.

The most common materials are:

- Brown kraft paper for strength and cost efficiency

- White kraft paper for cleaner branding and premium appearance

- Food-grade paper for direct contact with bakery or takeaway food

Paper weight matters more than many buyers expect.

Too light, and the bag tears at the bottom.

Too heavy, and costs rise without meaningful performance gain.

In commercial production, paper weight is selected based on bag size, load requirement, and intended use, not preference.

Step 2 – Printing Before Bag Forming

In professional production, printing happens before the bag is formed.

This allows better registration and faster output.

The two most common printing methods for paper bags are:

- Flexographic printing for large volumes and simple designs

- Offset printing for higher detail and brand-sensitive graphics

For food-related paper bags, printing is limited to non-food-contact surfaces. Ink systems are selected to minimize odor and migration risks.

Good printing should look clean.

Great printing should stay invisible after use.

If customers remember the bag because the ink smells, something went wrong.

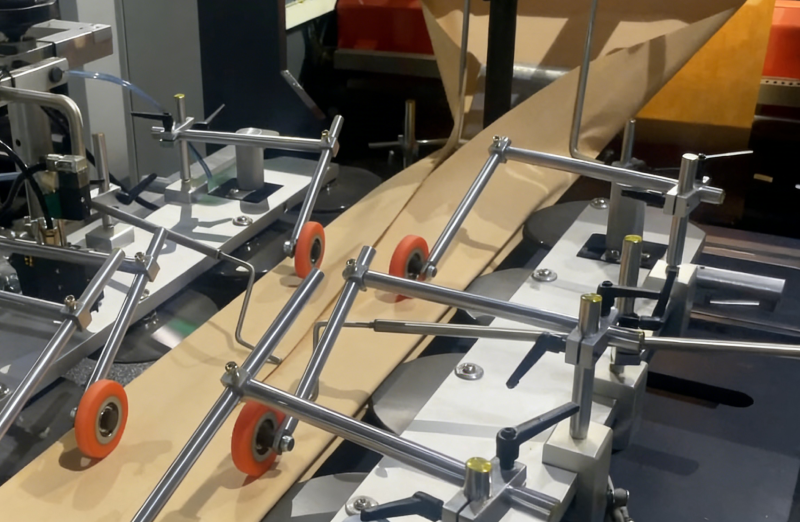

Step 3 – Cutting and Bag Forming

Once printed, the paper moves into the forming stage.

Here, machines cut, fold, and shape the paper into bags. This step determines:

- Bag dimensions

- Bottom structure

- Side gussets

Different bag styles require different forming logic:

- Flat paper bags for lightweight items

- SOS paper bags for takeaway and retail

- Handled paper bags for higher load and brand presentation

At this stage, precision matters. Small deviations multiply quickly in mass production.

A stable forming process is one of the clearest signs of a capable factory.

Step 4 – Gluing and Bottom Sealing

Glue is invisible.

But it carries the load.

Most commercial paper bags use water-based adhesive systems. They provide strong bonding while meeting food packaging safety expectations when properly applied.

- Critical bonding areas include:

- Bottom sealing points

- Side seams

Handle attachment zones

Weak glue application leads to one outcome: bottom failure.

In quality-focused factories, glue strength is tested under simulated load conditions, not just visual checks.

Step 5 – Handle Making (If Required)

Not all paper bags need handles.

But when they do, this step deserves attention.

Common handle types include:

- Twisted paper handles

- Flat paper handles

- Reinforced inner patch handles

Handles are usually produced separately and then attached during bag forming.

The weak point is not the handle itself.

It is the bond between handle and bag body.

Proper handle testing focuses on lifting cycles, not just static weight.

Step 6 – Quality Control During Production

Quality control is not one final inspection.

It is a sequence.

In professional paper bag production, checks typically include:

- Paper weight verification

- Print alignment and color consistency

- Glue bonding strength

- Dimensional accuracy

- Random load testing

Some defects are cosmetic.

Others are structural.

Experienced QC teams know the difference and prioritize accordingly.

This is where factory experience quietly protects buyers.

Step 7 – Packing, Warehousing, and Shipment

After production, bags are counted, packed, and stored.

Packing method affects:

- Transport efficiency

- Moisture resistance

- Handling damage

For export orders, palletization and container loading must align with shipping routes and warehouse conditions.

Paper bags are simple products.

But logistics mistakes can destroy their value quickly.

Common Buyer Questions About Paper Bag Production

Why do two suppliers quote very different prices for similar bags?

Because material selection, glue quality, and machine efficiency differ more than designs suggest.

Is thicker paper always better?

No. Proper structure matters more than raw thickness.

Can paper bags be customized easily?

Yes, but customization impacts printing method and minimum order quantity.

What causes most production delays?

Paper sourcing changes, printing revisions, and unstable forming setups.

Final Thoughts

Paper bags are simple only on the surface.

Understanding how they are made helps buyers avoid hidden risks and helps suppliers deliver consistent results. In commercial packaging, clarity beats complexity every time.

Looking for a Reliable Paper Food Packaging Manufacturer?

We manufacture high-quality disposable paper cup and food packaging, including paper cups, paper bowls, takeaway boxes, food containers, and paper bags.As a factory with a full production line, we support wholesale custom printing for bulk paper packaging orders.

→ Explore Our Custom Paper Packaging Solutions

→ Contact Us for Samples, Specifications & OEM Support

Let our team help you choose the right paper packaging solution for your product, market, and logistics requirements.